Accurate measurement | Fast response | Stable and reliable

Stiffness Tester

Product highlights and functional advantages

| Functional Modules | Description |

| One-touch operating system | Simple and intuitive, start testing quickly without complex settings |

| Multiple unit switching | Supports common international units (mN, gf.cm, mN·m) |

| Batch data processing | Supports continuous sampling, automatic data statistics and export |

| Embedded printing module (optional) | Can print test results for easy quality traceability |

Stiffness Tester Machine Standard

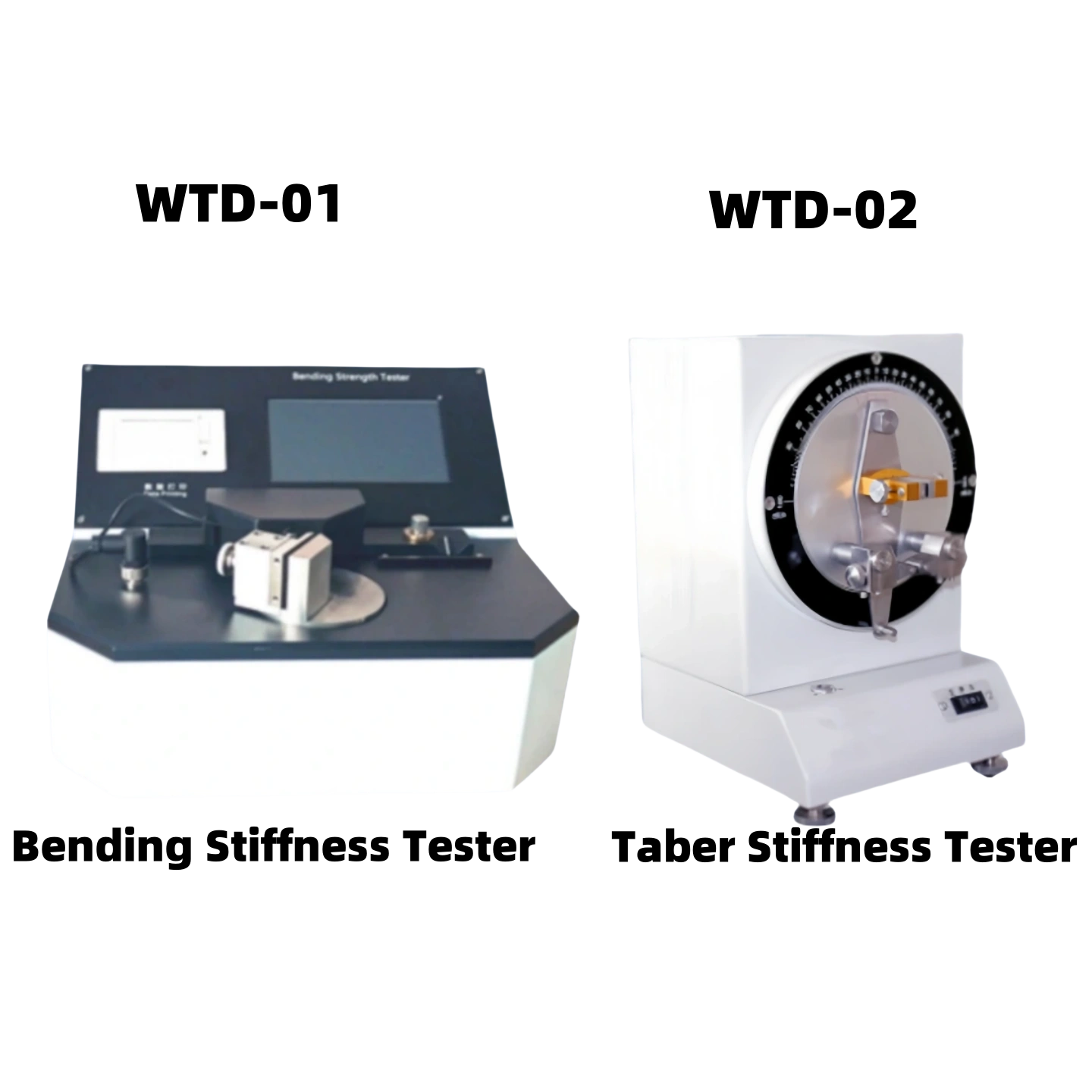

WTD-01

ISO2493-1, ISO 5628-2019,GB/T 2679.3, GB/T 22364

WTD-02

ASTM D3301, ASTM D5342, ASTM D5650,TAPPI T489, TAPPI T566, JIS P8125.2,BS ISO 2493.2 & ISO 2493.2

Stiffness Tester Machine Application

Measuring the bending stiffness of paper and paperboard, which reflects their resistance to bending deformation.

including but not limited to

- Plastic films

- Mica sheets

- Graphite sheets

- Composite sheets

- Other flat and flexible substrates

Principle

Simplified Working Principle of Bending Stiffness Tester

- One end of the sample is clamped, and the other end is free to bend.

- A force is applied to the free end at a set distance.

- The tester measures how much resistance or bending angle the sample shows.

- Bending stiffness is calculated from the force, angle, and sample size.

- It shows how well the material resists bending.

Simplified Working Principle of Taber Stiffness Tester

- Clamping: The sample is securely fixed to prevent movement during testing.

- Bending: It is bent to a set angle—15° for general materials, 7.5° for sensitive ones.

- Measurement: The instrument records the bending moment in mN·m.

- Stiffness: The bending moment directly indicates the material’s stiffness.

- Precision: Bending length and speed are precisely controlled for consistent results.

Specifications

WTD-01

| Sample Size | 38×80mm (Standard) |

| Testing Range | (0~10000)mN |

| Span range | 1~60mm, 5mm, 10mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm 8 grates for adjustment. |

| Span accuracy | ±0.1mm |

| Sensor accuracy | ±0.1% |

| Bending Angle | Adjustable between 1 to 92º |

| Angle Accuracy | ±0.1º |

| Angle measure | A single test can measure 3 different angles at the same time 1-90º can be set arbitrarily |

| Angular speed Control | 0.5 – 50 °/sec Three test angles and duration are independently adjustable |

| Testing Thickness | 0.01~5.0mm |

| Bending Time | Adjustable according to different material |

| Sample grip | Manual clamp, automatic reset after test |

| Clamping mode | Unlimited holding, can be non-destructive continuous clamping |

| Printer | Thermal Printer |

WTD-02

| Test range | 1~500 mN.m (in 7 ranges) |

| Indication error | ±2% |

| Bending length | 50mm±0.1mm |

| Testing speed | (200°±20°)/min |

| bending angle | 15°±0.3° and 7.5°±0.3° |

| Sample size | 38*70 mm |

| Dimension | 220*230*350mm |

| Net weight | 15kg |

| Power | AC 220V 50Hz |

stiffness test method

Stiffness Testing Importance

stiffness testing machine

Necessity of Testing

In this part, we will write a sub-headline briefly describing your company's unique value proposition.

Unique Value Proposition 1

In this part, we will write about what makes your business unique and the value people get from using your products or services over competitors.

2. Affects Packaging Quality

For packaging applications, the stiffness of paperboard determines its mechanical integrity, load-bearing capacity, and overall appearance.

3. Enhances User Experience

Stiffness directly impacts the tactile feel and usability of consumer-facing paper products.

4. Reflects Raw Material and Process Variations

Stiffness is not only a quality attribute but also a sensitive indicator of changes in raw material composition or processing conditions.

5. Supports Standard Compliance and Export Qualification

When exporting paper or paperboard products to international markets, compliance with standards like ISO 2493 or TAPPI T543 is often mandatory.

Stiffness TestIing Significance

Bending stiffness testing supports process optimization and quality assurance throughout production.

1.Fiber type, length, and orientation affect sheet rigidity

2.Sizing, calendaring, and drying processes can cause stiffness fluctuation

3.Coating defects or improper layer bonding may lead to reduced stiffness

Proper control of stiffness ensures a better user experience and reinforces brand perception.

1.Tissue papers with low stiffness may fold unevenly and feel flimsy

2.Writing paper lacking stiffness can crease easily and impair writing quality

3.Stationery and covers benefit from higher stiffness for a premium feel

Having a reliable stiffness testing capability enhances your global market access, product credibility, and customer trust.

1.Stiffness is frequently listed in buyer specifications

2.Certificates of Analysis (CoA) may require stiffness data

3.Third-party inspections typically include bending stiffness tests

Comprehensive Material Quality Control Testing Solutions

Cell Instruments Advantages

Professional manufacturer background 1

With many years of R&D and production experience, we focus on packaging, medicine, food, and electronics. We have a strong R&D team and modern manufacturing system to ensure leading product quality and technical level.

Strong custom development capabilities 2

With deep technical accumulation, we provide tailor-made solutions, including function adjustment, software customization, and automation transformation, to flexibly respond to various testing needs and improve testing efficiency.

Complete after-sales service system 3

With a technical support and after-sales service network covering the national and overseas markets, we provide full-service services such as operation training and remote diagnosis to ensure that customers are worry-free and minimize downtime.

Frequently asked questions

Q1: What thickness range of paper can your equipment test?

A1: It can test from standard printing paper (e.g., 80g/m²) to corrugated board (0.3mm–1.5mm). Custom clamps are available for special thickness requirements.

Q2: Can the stiffness value be calculated automatically?

A2: Yes, the instrument automatically displays the torque value and converts it to the preset stiffness unit upon test completion.

Q3: Is frequent calibration required? How is it done?

A3: Calibration is recommended every 6 months. The device features automatic zeroing and calibration functions for easy operation.

Q4: Can the test data be exported for further analysis?

A4: Yes, data can be exported via USB in CSV or Excel format. The system also supports printer connection and LIMS integration.

Q5: How can I get pricing and technical information?

A5: Click the “Get a Quote” button on the page or contact our online support. We will provide complete technical documentation and a professional quotation.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985